Comprehensive Guide to Tactile Plate PBR Textures for Realistic Industrial Surfaces

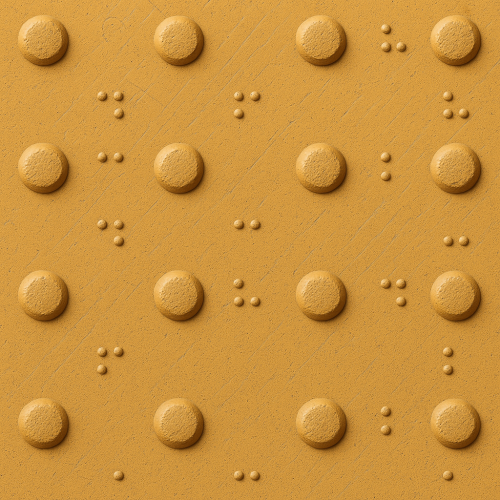

Capturing tactile plate textures with precision requires a deliberate approach to acquisition that honors the material’s distinct physicality—namely the raised bumps, subtle wear patterns, and the interplay of surface finish characteristics. Given the importance of these details for generating physically based rendering (PBR) maps that faithfully reproduce tactile plates in digital environments, practitioners commonly turn to high-resolution photogrammetry and 3D scanning methods, each with their own strengths and logistical considerations.

Photogrammetry remains a go-to technique for capturing tactile plates, particularly when the goal is to acquire high-fidelity albedo and surface detail data simultaneously. The process involves photographing the plate from multiple angles under controlled lighting to ensure consistent exposure and minimal specular highlights that can confound texture extraction. High dynamic range (HDR) image capture is often recommended to retain subtle tonal variations in the albedo, especially since tactile plates tend to have subdued color palettes with nuanced grime or wear. Using a macro lens with a narrow aperture (f/8–f/16) helps maximize depth of field, which is critical for keeping the entire tactile surface—especially the raised bumps—in sharp focus.

To accurately capture the small-scale height variations intrinsic to tactile plates, the photogrammetry workflow must incorporate fine detail capture strategies. This often means increasing the image overlap to 80–90% and reducing the camera-to-subject distance to maximize pixel density per unit of surface area. The resultant dense point cloud should be inspected and cleaned to preserve the integrity of the raised nodules while avoiding noise artifacts that can introduce false microgeometry. Post-processing in software such as RealityCapture, Metashape, or Meshroom should involve generating high-resolution mesh outputs with a vertex count sufficient to support normal and height map baking at the desired texture resolution (typically 4K or 8K for tactile plates due to their close-up viewing scenarios).

3D scanning, particularly structured light or laser scanning, offers a complementary or alternative approach to photogrammetry when capturing tactile plates. Scanners with sub-millimeter accuracy can more reliably record the precise geometry of the raised bumps and subtle deformations caused by wear or dirt accumulation. This geometric accuracy is critical for baking displacement or height maps that drive convincing parallax effects in real-time engines. However, 3D scanning often lacks direct color capture, necessitating a separate high-resolution image capture phase for the albedo map. The alignment of color data with scanned geometry requires careful calibration using targets and fiducials, ensuring that the texture maps correspond pixel-perfectly to the mesh UVs.

When configuring the scanning setup, one must pay particular attention to the surface reflectivity and ambient lighting conditions. Tactile plates, often composed of durable plastics or metals with matte finishes, can exhibit low specular reflection, which benefits structured light scanning by reducing noise. However, any surface gloss or dirt layers can produce scanning artifacts, so surface cleaning or application of a removable matte spray might be necessary to optimize scan quality. Calibration routines should be meticulously followed to maintain spatial accuracy, which directly impacts the fidelity of normal and height maps derived from the scans.

Regardless of the acquisition method, the translation from raw data to PBR texture sets requires deliberate authoring to preserve tactile plate characteristics. The albedo map must be free of baked-in shadows or highlights, necessitating careful color correction and possibly the use of texture projection techniques to remove lighting inconsistencies. For roughness maps, capturing micro-variation is paramount; tactile plates often possess subtle differences in surface wear caused by foot traffic or environmental exposure, which affect local specularity and glossiness. These variations can be extracted from photogrammetric data by analyzing specular reflections under controlled lighting or, in scanning workflows, inferred from spatially varying surface roughness measured during acquisition or approximated during authoring.

Normal maps should be generated from the high-resolution mesh, emphasizing the raised bumps’ geometry without exaggerating their height beyond physical plausibility. Excessive normal map intensity can result in unnatural lighting responses, so baking parameters should be calibrated carefully, ideally by comparing renders in engines like Unreal Engine or Blender’s Eevee and Cycles to validate the perceived depth and shading fidelity. Ambient occlusion (AO) maps should be baked from the high-poly mesh to capture the shadowing effects in crevices around the bumps and wear depressions, adding depth and realism when combined multiplicatively with the albedo in shader networks.

Height maps are especially important for tactile plates due to their pronounced relief; these maps can be employed for parallax occlusion mapping or tessellation in real-time engines, enhancing the tactile feel visually and interactively. Accuracy in height map generation hinges on the fidelity of the base mesh and the precision of the baking process, which should include anti-aliasing and filtering steps to avoid artifacts like banding or aliasing on edges. Height map resolution should match that of the albedo to maintain consistency in detail perception.

Metallic maps are generally not applicable for typical tactile plates, as these surfaces are predominantly non-metallic polymers or painted metals with dielectric properties. However, if the plate contains metallic components or wear exposes metal beneath, a binary or grayscale metallic mask can be authored manually or derived from reflectance data to fine-tune the PBR shader response.

Tiling and micro-variation present a unique challenge in tactile plate texturing. Since tactile plates are often installed in large, repeating patterns, creating seamless PBR textures requires careful consideration. The acquisition process rarely produces naturally tileable data, so manual authoring in texturing software like Substance Painter or Designer is necessary. Micro-variation can be introduced by blending multiple scans or photogrammetry captures of plates exhibiting different wear stages or dirt patterns, creating texture sets that avoid obvious repetition. Additionally, procedural noise layers can be overlaid on roughness and albedo maps to simulate small-scale irregularities, maintaining visual interest over large surfaces without compromising physical accuracy.

Optimization for real-time engines demands balancing texture resolution with performance constraints. Given the proximity in which tactile plates are often observed in VR or architectural visualization, higher resolutions are justified, but careful mipmap generation and texture streaming strategies should be employed. Baking out combined maps such as roughness integrated with ambient occlusion or height encoded into normal maps can reduce shader complexity and improve runtime efficiency. Using engine-specific shader models—Unreal Engine’s material editor or Blender’s principled BSDF shader—facilitates accurate reproduction of the tactile plate’s physical characteristics when feeding these maps into the relevant channels.

In summary, acquiring tactile plate PBR textures is a multi-stage process beginning with precise high-resolution data capture through photogrammetry or 3D scanning, progressing through meticulous map authoring to preserve subtle surface details, and culminating in optimized texture sets tailored for real-time rendering engines. Each step demands rigorous calibration, careful attention to the tactile plate’s unique surface topology and material response, and thoughtful integration of micro-variation and tiling considerations to achieve a convincing and physically accurate digital representation.

Creating tactile plate textures within a physically based rendering (PBR) workflow demands a nuanced approach that balances the precise replication of material properties with practical considerations for seamless integration in real-time engines such as Unreal Engine or offline renderers like Blender’s Cycles. These textures must convincingly convey the distinct surface qualities of tactile plates—typically metal or coated substrates featuring intricate patterns, subtle abrasions, and surface wear—while maintaining consistency in lighting response, durability under various view angles, and efficient performance.

When authoring tactile plate textures procedurally, the emphasis lies in generating base color (albedo), roughness, normal, ambient occlusion (AO), and height maps algorithmically, often driven by noise functions, pattern generators, and layered masks. This method excels in producing perfectly tileable textures with infinite variation potential, crucial for large surfaces or modular asset reuse. Starting with the albedo, procedural workflows simulate metal finishes by combining base hues typical of metals (steel, aluminum, or painted metal powders) with subtle chromatic variations derived from noise or gradient maps. These variations mimic the natural inconsistencies in metal pigmentation caused by manufacturing processes or environmental exposure. The albedo must be calibrated to remain energy-conserving; metallic areas generally have near-zero diffuse reflection, while painted or powder-coated regions exhibit diffuse coloration with minimal specular tinting.

Roughness maps generated procedurally for tactile plates often incorporate multi-scale noise layers to replicate the complex interplay of smooth metal surfaces and rough powder coatings. A base roughness value is modulated by fine-grain noise to simulate micro-scratches or particulate texture, overlaid with larger-scale patterns representing powder accumulation or wear. This layering ensures the roughness channel responds realistically to varying lighting conditions, affecting highlight sharpness and glossiness. A key procedural technique involves using curvature or edge detection filters on height or normal maps to selectively increase roughness along edges or raised plate features, simulating natural abrasion.

Normal map generation is pivotal for tactile plates, as their defining characteristic is a raised or recessed pattern providing tactile feedback. Procedurally, this is achieved by creating height maps from geometric primitives or noise-driven displacement patterns, which are then converted into normal maps via derivative calculations. The patterns must be accurately tiled and aligned with the UV space to avoid visible seams. To introduce micro-variation, a secondary normal detail layer—derived from fine noise or scratch maps—is blended additively, enhancing surface complexity without overwhelming the primary geometric pattern.

Ambient occlusion maps, though often baked from high-poly geometry, can be approximated procedurally by simulating shadowing from the tactile pattern’s geometry using curvature-based ambient occlusion techniques or screen-space AO filters. The AO map should subtly darken recesses without flattening the tactile contrast, preserving readability of the pattern under indirect lighting. Height maps serve both as displacement references in offline renders and as input for parallax occlusion mapping or tessellation in real-time engines. Procedural height maps benefit from multi-frequency noise superimposed on the base pattern, adding realistic depth variation that enhances the tactile feel.

Photo-based texture authoring complements procedural methods by providing real-world references that capture the nuanced imperfections of tactile plates—such as powder coat granularity, subtle color shifts, and abrasion marks that are difficult to replicate purely algorithmically. High-resolution photographs of actual tactile plates under diffuse and directional lighting form the basis of albedo extraction. These photos require careful correction to remove lighting artifacts, shadows, and specular highlights to isolate the diffuse color accurately. Techniques such as color de-bleeding and histogram equalization help maintain color fidelity and consistency across texture tiles.

For roughness and metallic maps, photo-based workflows often involve capturing multiple images under controlled lighting setups (e.g., cross-polarized lighting) to separate diffuse and specular components. These images are processed to derive roughness variations linked to surface irregularities like coating thickness changes or abrasion patterns. Manual painting or procedural masks can then isolate abrasion marks—typically found on raised edges or high-contact areas—and assign them lower roughness values to simulate polished wear, or higher roughness to represent scuffed or corroded surfaces. Metallic maps, while generally uniform for metal tactile plates, may require subtle variation in photo-based textures if the plate includes painted or non-metallic sections, necessitating precise masking and channel blending.

Normal maps derived from photogrammetry or photometric stereo capture the actual microgeometry of tactile plates, including dents, scratches, and coating texture. However, these captures often contain noise and require cleanup via image editing software or specialized tools like Substance Designer. Height maps can be extracted from displacement captures or converted from normal maps but must be calibrated carefully to avoid exaggerated displacements in real-time rendering. This calibration involves adjusting the height map’s contrast and integrating it with engine-specific tessellation settings or parallax occlusion parameters.

Tiling and micro-variation are critical considerations for both procedural and photo-based tactile plate textures. Procedural methods inherently facilitate seamless tiling by manipulating UV-aware noise and pattern generation algorithms. Nonetheless, care must be taken to avoid repetitive artifacts, which can break immersion. Introducing non-uniform noise layers and randomizing abrasion mask positions help break tiling patterns. For photo-based textures, creating tileable maps involves a combination of careful image cropping, edge blending, and clone stamping to eliminate visible seams. Micro-variations can be enhanced by overlaying procedural noise or adding subtle baked surface dirt and wear layers in the roughness and albedo channels.

Calibration across all maps is essential to ensure the tactile plate’s physical and visual properties align accurately within the PBR framework. This includes verifying that metallic and roughness values adhere to energy conservation principles, that normals are correctly oriented and normalized, and that AO and height maps complement each other without causing excessive darkening or displacement artifacts. A practical approach involves iterative testing within target engines like Unreal Engine or Blender, adjusting texture parameters in real time under various lighting conditions to confirm that tactile patterns maintain their intended visibility and tactile impression without introducing shading anomalies or performance penalties.

Optimization strategies focus on balancing texture resolution and channel packing. For instance, combining roughness, metallic, and AO maps into single RGB textures reduces draw calls and memory usage, which is beneficial for real-time applications. Normal and height maps are often kept separate due to their differing sampling and filtering requirements. Utilizing compression formats compatible with target engines—such as BC5 for normal maps and BC7 for color data in Unreal Engine—preserves texture quality while minimizing footprint. Moreover, generating mipmaps that respect the tactile pattern’s detail scale prevents blurring of critical edges and maintains pattern legibility at distance.

In engine usage, tactile plate textures benefit from material setups that leverage PBR channels effectively. Unreal Engine’s material editor allows for dynamic blending of abrasion masks and procedural noise textures to simulate wear over time or in response to gameplay events. Similarly, Blender’s shader nodes enable layered normal maps and roughness variation driven by vertex colors or texture masks. Implementing tessellation or parallax occlusion mapping with calibrated height maps enhances the tactile impression without the cost of additional geometry.

Ultimately, the integration of procedural and photo-based authoring techniques provides a robust toolkit for generating tactile plate PBR textures that are both visually convincing and performant. Procedural methods offer scalability and flexibility, ideal for base patterns and micro-variation, while photo-based inputs anchor the textures in real-world authenticity, capturing subtle imperfections that elevate realism. Through meticulous calibration, tiling refinement, and optimization, these workflows ensure that tactile plate textures fulfill their dual role as functional surface indicators and aesthetic elements in diverse digital environments.

Creating physically based rendering (PBR) maps for tactile plate textures demands meticulous attention to both the geometric intricacies of the raised patterns and the specific material characteristics that define their visual and tactile identity. The primary challenge lies in capturing the subtle interplay between light and surface detail—especially the raised, often repetitive embossed or debossed motifs typical of tactile plates—while ensuring these features translate convincingly across diverse rendering engines like Unreal Engine or Blender’s Cycles and Eevee. Each PBR map serves a distinct purpose in defining the surface’s response to lighting and environmental factors, and their generation must be approached with a workflow that balances accuracy, efficiency, and flexibility.

The BaseColor (albedo) map for tactile plates generally requires careful color calibration and the exclusion of baked lighting information to maintain physical correctness. Since tactile plates are commonly fabricated from metals such as stainless steel, aluminum, or painted steel, the BaseColor tends to be monochromatic or subtly variegated. When authoring this texture, one should acquire high-resolution reference photographs under diffuse, neutral lighting to avoid specular highlights and shadows contaminating the color data. Photogrammetry or high-quality scans can help capture surface color variations, including wear, oxidation, or paint chipping, which add realism without compromising physical accuracy. If working procedurally, subtle noise or grunge layers can simulate micro-scratches or dust accumulation, essential for breaking up uniformity and preventing overly synthetic appearances. It is crucial to ensure the BaseColor remains strictly within the sRGB color space and to validate the texture under linear workflow conditions in the target engine to avoid color shifts.

Normal map generation is paramount for tactile plates due to the pronounced relief of the raised patterns that define their tactile function. These maps simulate small-scale surface details by perturbing the surface normals used in lighting calculations, enhancing the perception of depth without adding geometry. Normal maps can be derived from high-poly sculpted models of the plate’s pattern or generated from height maps using tools like xNormal, Substance Designer, or Blender’s baking system. When baking normals, consider the scale of the patterns: the height differential between the raised features and the base plate must be accurately captured to avoid flattening or exaggeration. A common pitfall is producing normal maps with overly sharp edges that create unnatural lighting artifacts; employing subtle beveling or smoothing on the high-poly model before baking can alleviate this. Micro-variation within the normal map—such as slight surface imperfections, dents, or subtle embossing inconsistencies—is essential to prevent uniform lighting responses that betray procedural origins. When integrating normal maps in Unreal Engine or Blender, ensure the normal space conventions match (typically tangent space) and that the maps are stored in the correct channel order (often OpenGL or DirectX standards).

Roughness maps control the microsurface scattering of light, determining whether reflections appear sharp and mirror-like or diffuse and matte. For tactile plates, roughness varies significantly across different material states and wear conditions. For example, polished metal tactile plates will have low roughness values on the raised areas, while recessed or worn parts may accumulate dirt or oxidation, increasing roughness. When authoring roughness maps, grayscale images are used where black indicates a perfectly smooth surface and white denotes maximum roughness. These maps can be hand-painted or procedurally generated using software like Substance Designer, which can synthesize wear patterns and edge aging using curvature and ambient occlusion inputs. It is vital to correlate roughness values with the physical material being represented; for instance, stainless steel tactile plates commonly exhibit roughness values in a mid-range with localized variations rather than extreme smoothness or roughness. Calibration involves physically referencing materials under HDR environment maps to match reflection intensity and sharpness. Additionally, avoid layering roughness with specular or metallic information, as this can cause unpredictable results in PBR shading models.

The Metallic map is often a simple binary representation for tactile plates, especially when the material is a metal or a non-metal. Since tactile plates are predominantly metallic, this map typically consists of white (value 1) for all pixels, indicating purely metallic surfaces, but there are exceptions. Painted or coated tactile plates, or those with plastic or rubberized components, require careful masking of metallic versus non-metallic areas. Metallic maps influence the Fresnel effect and the color of reflections and must be aligned with the BaseColor map to avoid physically implausible shading. When authoring metallic maps, it is advisable to keep values strictly at 0 or 1 since intermediate values are rare in real-world materials and can introduce confusion in the shader pipeline. This map is critical in engines like Unreal Engine, which use it to blend between dielectric and metallic BRDFs.

Ambient Occlusion (AO) maps are baked from high-poly geometry and represent self-shadowing effects caused by nearby surface features occluding ambient light. For tactile plates, AO enhances the visibility of the raised patterns by darkening crevices and recesses, which increases depth perception and realism. AO maps must be carefully baked with high resolution and optimized to avoid artifacts such as bleeding or over-darkening flat areas. It is beneficial to bake AO independently of global illumination so that it can be combined dynamically in the shader with real-time lighting. When baking, the cage settings and ray distance must be tuned to capture the fine details of the tactile plate’s embossing without bleeding into unrelated areas. Furthermore, micro-occlusion details that simulate surface roughness can be integrated into the AO map or separated into a cavity map, depending on the workflow. In engine usage, AO is typically multiplied with the BaseColor or plugged into the dedicated AO slot in the material editor, amplifying the perception of surface complexity.

Height or Displacement maps provide actual geometric displacement information, allowing rendering engines to offset vertices or pixels along the view vector to simulate real surface relief. For tactile plates, accurate height maps are crucial to represent the raised patterns physically, especially in close-up renders or when using tessellation or parallax occlusion mapping. Unlike normal maps, height maps describe scalar height values, usually stored as grayscale images, where white represents the highest points and black the lowest. To generate these maps, one can start from the high-poly sculpt, capture detailed depth information, and then process it to optimize the range and contrast, ensuring the raised patterns stand out clearly but without introducing unnatural sharpness or artifacts. Height maps are often used in combination with normal maps to provide a layered approach to surface detail: displacement for large-scale geometry shifts and normals for fine micro-details. In engines like Unreal Engine, enabling tessellation or virtual displacement requires careful balancing of performance and visual fidelity, so height map resolution and detail level should be optimized accordingly. Blender’s Cycles supports true displacement, while Eevee uses parallax or bump mapping techniques that rely on height data for visual approximation. It is important to calibrate the height map intensity to avoid clipping geometry or exaggerated relief that breaks silhouette integrity.

Throughout the PBR map creation process, tiling and seamlessness are critical for tactile plates, which often cover large surfaces. The raised patterns are usually repetitive, so generating tileable textures without visible seams is essential. Techniques such as edge padding, seamless clone stamping, or procedural pattern generation can be employed. Micro-variation in pattern positioning, color, and surface imperfections must be introduced to avoid a monotonous appearance and reduce the “copy-paste” effect that can detract from realism. This can be achieved by blending multiple texture samples, adding noise layers, or using mask-driven variation in roughness and normal maps.

Optimization is another key consideration. High-resolution maps provide fidelity but can severely impact performance, particularly in real-time applications like Unreal Engine. Therefore, it is advisable to bake or author multiple levels of detail and leverage engine features such as mipmapping and texture compression formats that preserve quality. Channel packing, where ambient occlusion, roughness, and metallic maps are combined into single textures using different color channels, can reduce memory footprint and improve shader efficiency, but requires careful alignment and consistent gamma handling.

Finally, calibration against physically measured reference data or real-world material scans ensures the tactile plate textures behave predictably under various lighting conditions. Using HDR environment maps and IBL workflows in rendering previews helps validate the PBR maps before deployment. Adjustments to roughness and metallic values can be subtle yet impactful, and iterative refinement guided by physically based principles ensures the final tactile plate textures achieve the desired photorealism and tactile fidelity across platforms and engines.