High Quality PBR Furniture Chipboard and MDF Textures for Realistic 3D Visualization

Beginning with the foundational albedo capture, it is critical to isolate the true base color of chipboard and MDF surfaces without contamination from specular highlights or shadows. Due to their matte, fibrous nature, these materials often exhibit low specularity but possess complex subsurface light scattering and fine surface irregularities that influence their perceived color. Use of a high-resolution DSLR or mirrorless camera equipped with a macro lens is standard practice, paired with a diffuse lighting setup such as a light tent or multiple softbox sources to minimize harsh shadows and specular spots. When shooting, capturing raw, linear 16-bit images and applying a calibrated color target—such as an X-Rite ColorChecker—enables precise color correction and white balance in post-processing, preserving accurate albedo data. Care must be taken to avoid overexposure or clipping, as highlight compression can obscure subtle tonal variations critical for realistic texturing.

For surfaces like chipboard and MDF, photogrammetry remains a powerful method to acquire both color and geometric detail, but it must be adapted to the material’s relatively low specular contrast and fine surface texture. Multi-view image capture should be conducted under consistent lighting conditions, ideally with diffuse illumination to prevent specular reflections from confounding the photogrammetric reconstruction algorithms. Using high overlap between images—commonly 75% or more—and a sufficient number of angles ensures dense point clouds and accurate mesh generation. Capturing micro-variation such as sanding marks and glue residue requires extremely high image resolution and close-range photography. Supplementing photogrammetry with structured light scanning or laser scanning can enhance normal and height detail, particularly for subtle depressions or raised fibers that are difficult to resolve solely through photogrammetric depth maps.

When extracting roughness and normal maps, consider the inherent micro-roughness and surface grain of chipboard and MDF. Their roughness tends to be medium to high due to the fibrous and porous structure, but localized variations occur around glue patches or sanding imperfections. To capture this, a combination of photometric stereo and close-range scanning is effective. Photometric stereo involves capturing images under varying directional lighting to compute surface normals and fine detail maps. This approach can reveal the anisotropic sanding marks and minute surface undulations that generic normal maps may miss. The resulting normal maps should be calibrated to match the tangent space conventions of the target engine, whether Unreal Engine’s left-handed coordinate system or Blender’s right-handed setup, to prevent shading artifacts.

Ambient occlusion (AO) maps are essential to simulate the subtle shadowing within the porous fiber clusters and the edges of chipboard flakes. AO data can be baked from high-resolution meshes generated during photogrammetry or laser scanning. Generating AO maps at different scales allows for layering of macro and micro occlusion details, enhancing realism. When baking AO, it is crucial to ensure the mesh is clean, watertight, and free of non-manifold edges to prevent artifacts. Additionally, small-scale surface features such as sanding gouges and glue residue often introduce localized occlusion effects that contribute to perceived depth and texture complexity, thus high-resolution baking or ambient occlusion captured via photometric methods can improve the final texture fidelity.

Height maps derived from the geometry data are indispensable for parallax or displacement effects in modern renderers. The fibrous structure and glue patches on chipboard and MDF produce minute height variations that should be captured with sub-millimeter accuracy. Structured light scanners or laser scanners with micrometer precision excel in this domain, delivering height data that can be converted into grayscale displacement or parallax occlusion maps. When integrating these maps into Unreal Engine, it is essential to optimize map resolution and compression settings to balance visual fidelity and runtime performance. Similarly, Blender’s displacement modifiers leverage these height maps for physically accurate surface deformation in Cycles or Eevee renderers, but require UV maps with minimal stretching and appropriate subdivision to prevent artifacts.

Metallic maps are generally not applicable for chipboard and MDF, as these materials are non-metallic by nature. In PBR workflows, the metallic channel should remain at zero or black to ensure physically plausible reflectance. However, the roughness channel requires careful calibration. Due to the matte finish, roughness values typically range from medium (0.5) to high (0.9), but local variation exists depending on surface treatment and glue presence. Capturing roughness maps can be approached via specialized roughness scanning devices or estimated indirectly by analyzing the specular response under controlled lighting. In the absence of dedicated equipment, a photometric stereo setup combined with albedo maps allows for approximating roughness through inverse rendering techniques.

Tiling and micro-variation are critical considerations for applying chipboard and MDF textures in large furniture scenes. These materials exhibit natural randomness in fiber distribution, particle size, and glue application that prevent seamless repetition without noticeable patterns. To address this, capture multiple texture tiles from different areas of the source material, ensuring that each tile includes unique sanding marks and glue patterns. These tiles can then be blended or randomized in the shader using masks or vertex color data to break repetition. Additionally, procedural noise overlays or micro-detail normal map layers can be used to introduce subtle variation at the shader level without increasing texture memory significantly.

Calibration throughout the acquisition and authoring pipeline is paramount to maintain consistency and physical accuracy. Color calibration must be verified with calibrated monitors and color profiles to ensure that albedo maps correspond to actual material reflectance. Geometric calibration involves verifying scanner accuracy with calibration targets and validating mesh dimensions against physical samples. When integrating textures into engines like Unreal or Blender, test renders under standardized lighting setups help fine-tune roughness and specular parameters to match real-world observations. Maintaining a strict naming and metadata convention within texture sets facilitates reuse and modification during iterative development.

Optimization for engine usage encompasses balancing resolution, compression, and channel packing. Chipboard and MDF textures rarely require extremely high-resolution maps beyond 2048x2048 for most furniture assets, but capturing at higher resolutions during acquisition allows for downsampling with better preservation of detail. Channel packing—combining roughness, AO, and metallic into single texture channels—is effective here, with the metallic channel unused or reserved for future material variants. In Unreal Engine, leveraging virtual texturing or texture streaming can help manage memory usage when deploying large scenes with multiple furniture assets. Blender users should consider baking normal and displacement maps into optimized formats compatible with Eevee’s real-time renderer or Cycles’ path tracer.

Finally, practical tips for acquisition include maintaining consistent environmental conditions during capture to reduce variability, using polarizing filters to minimize residual specular highlights on semi-glossy glue spots, and physically cleaning the surface to remove dust or transient contaminants. Where possible, capturing reference measurements of surface roughness and gloss using handheld meters can provide ground truth data to validate texture maps. Combining these methodologies yields a robust, physically accurate representation of chipboard and MDF surfaces that supports compelling PBR materials in modern 3D pipelines.

Creating physically based rendering (PBR) textures for furniture materials such as chipboard and medium-density fiberboard (MDF) requires a nuanced approach that balances the organic irregularity of wood grain with the clearly manufactured aspects of laminates, paints, edge banding, and veneer overlays. Both procedural generation and photographic capture have distinct strengths and limitations, and combining these methods often yields the most convincing and versatile results. This section delves into the technical considerations and workflows necessary to author high-quality PBR textures that faithfully represent these complex materials within real-time engines like Unreal Engine and offline renderers such as Blender’s Cycles, with an emphasis on practical calibration, optimization, and micro-variation techniques.

Starting with the base color (albedo) channel, photographic resources remain the most reliable source for capturing the subtleties of both wood grain and manufactured surfaces. High-resolution, diffuse-balanced images are essential to preserve accurate color information without baked lighting or specular interference. For chipboard and MDF, this often involves carefully controlled diffuse lighting setups that minimize shadows and highlight the fibrous, compressed structure of the material. When capturing laminates or painted finishes, a neutral light environment facilitates the separation of diffuse versus specular components during texture extraction. Photogrammetry and flatbed scanning can be employed for larger panels, but planar captures with a macro lens often yield higher detail and better control for tiling textures.

Photographic acquisition must be accompanied by precise calibration against known reference values to ensure physically plausible reflectance. This entails verifying albedo values against standardized color charts and measuring specular reflectance using gonioreflectometers or calibrated HDRI captures if available. Without such calibration, textures may appear unnaturally saturated or dull once plugged into PBR workflows, disrupting the material's realism under dynamic lighting conditions. For chipboard and MDF, the albedo typically falls into muted beige or light brown tones, but the laminated surfaces can range widely depending on manufacturer specifications, demanding bespoke calibration for each variant.

Procedural generation techniques complement photographic methods by enabling infinite variation, seamless tiling, and parametric control over wood grain, fiber orientation, and laminate patterns. Node-based systems in software like Substance Designer or Blender’s Shader Editor can simulate the stochastic structure of pressed wood fibers and the layered construction of laminates. Procedural noise functions, such as Perlin or Worley noise, can be combined with directional distortion to mimic the random yet anisotropic nature of wood grain and fiberboard textures. Layer blending modes simulate the effect of paint or laminate coatings over the base chipboard, adjusting albedo and roughness accordingly to reflect their typically smoother, less porous surfaces.

Procedural workflows excel at generating height and normal maps that capture subtle surface relief without the need for extensive photographic displacement capture. The compressed fibers of MDF and chipboard exhibit fine-scale bumpiness and occasional larger voids or knots, which can be modeled by combining fractal noise with directional grain patterns. For edge banding and veneer effects, procedural masks enable the precise delineation of surface transitions, allowing for sharp changes in roughness and normal detail that replicate the thin strips of plastic or wood veneer applied to panel edges. These masks are crucial for avoiding texture bleeding and ensuring that edge treatments react correctly to lighting and wear over time.

Photographic and procedural data often converge in the creation of roughness maps. Manufactured finishes like laminates and paints exhibit lower roughness values with sharper specular highlights, while raw chipboard and MDF surfaces are inherently more matte, with higher and more spatially varied roughness. Photographic roughness extraction can be tricky, often requiring specialized equipment or indirect inference from specular observations under controlled lighting. Procedural roughness maps can fill this gap by simulating micro-roughness associated with fiber orientation and surface treatment variability. Combining photographic base color with procedurally generated roughness and normal maps often yields the best balance between realism and artistic control.

Ambient occlusion (AO) maps are critical for enhancing visual depth in furniture materials, particularly around edge banding seams, veneer folds, and chamfered edges common in cabinetry. AO can be baked from high-poly meshes or procedurally generated using curvature and cavity detection filters applied to normal maps. For chipboard and MDF, subtle AO accentuates the fibrous texture and compressive nature of the material, adding perceived depth without overwhelming the diffuse color. Care must be taken to avoid overly dark AO contributions, which can produce unnatural shadows when combined with dynamic lighting in real-time engines.

Height maps serve a dual purpose in PBR workflows for these materials. They provide parallax and displacement data essential for close-up visual fidelity and enhance normal map generation through height-to-normal conversion algorithms. The micro-structure of chipboard and MDF lends itself well to height map extraction from high-resolution scans or procedural noise layers, capturing the compressive texture and occasional surface irregularities. For laminates and painted finishes, height maps are generally flatter and should reflect the smoothness and subtle edge rounding characteristic of these coatings. Edge banding height maps must precisely represent the thin profile of the applied strip, often requiring hand-tuned gradient masks to prevent artifacts during tessellation or parallax occlusion mapping.

The metallic channel is usually not applicable for chipboard or MDF surfaces, as these are dielectric materials. However, some laminates with metallic flakes or foil inlays may warrant a non-zero metallic value. In such cases, photographic or procedural metallic maps should be carefully calibrated to avoid overemphasizing metallic behavior, which can cause unrealistic reflections and lighting responses.

Tiling and micro-variation strategies are paramount for avoiding repetitive patterns that break immersion, especially when mapping large furniture surfaces. Photographic textures require careful seam removal and edge blending using tools like Texel Density adjustments and corner-padding techniques to ensure uniform scaling across different mesh areas. Procedural textures inherently offer infinite tiling but may lack the organic randomness found in photographic sources. Hybrid workflows combine the benefits of both, applying procedural noise overlays to photographic base colors or modulating roughness and normal maps procedurally to introduce subtle variations across the surface.

Micro-variation can also be introduced by layering dirt, wear, and scratch maps, which are essential for conveying usage history on furniture surfaces. These overlays are often authored procedurally or captured photographically and blended using masks derived from AO or curvature maps to localize effects to edges and high-contact areas. This approach is particularly effective in simulating the wear on edge banding, where paint may chip or veneer peel, providing a convincing narrative of real-world use.

Optimizing these PBR textures for real-time engines involves balancing resolution and channel packing. Common practice includes packing roughness, metallic, and ambient occlusion into a single texture’s RGB channels to reduce shader sample costs. Normal maps are typically stored separately to maintain precision. For Unreal Engine, texture streaming and mipmap generation must be calibrated to preserve fine detail without excessive memory consumption. Using anisotropic filtering and appropriate compression profiles ensures crispness of wood grain and laminate details across viewing distances. Blender users benefit from procedural shaders that allow dynamic parameter tweaking without texture memory overhead, though final exports for game engines require baking these procedural elements into texture maps.

Calibration of textures against engine lighting models is critical. Both Unreal Engine and Blender implement different interpretations of roughness and normal space that can affect the final appearance. Artists should use engine-specific preview tools and physically based lighting setups—such as HDRI environments with neutral light probes—to iteratively adjust texture parameters. This ensures that subtle features like the sheen of a laminate or the matte fibrous quality of chipboard behave consistently under diverse lighting scenarios.

In summary, the creation of PBR textures for chipboard and MDF furniture surfaces benefits greatly from a hybrid approach that leverages the detailed fidelity of photographic captures and the flexibility of procedural generation. Attention to channel accuracy, micro-variation, tiling, and calibration within engine pipelines is essential to achieving materials that convincingly replicate the interplay between natural wood fibers and manufactured coatings. By integrating these techniques, artists can produce textures that not only meet technical requirements for real-time rendering but also convey the tactile qualities and visual complexity integral to realistic furniture materials.

The creation and calibration of PBR (Physically Based Rendering) texture maps for chipboard and MDF surfaces require a precise, methodical approach to capture the unique visual and tactile qualities of these engineered wood materials. Unlike natural hardwoods, chipboard and MDF exhibit relatively uniform coloration but possess subtle micro-variations and complex surface characteristics that demand careful attention in texture generation to avoid flat or artificial results. The process typically involves the generation of multiple complementary maps—albedo, normal, roughness, ambient occlusion, and height—with metallic maps generally omitted due to the inherently non-metallic nature of these materials. Each map serves a distinct function in simulating the interaction of light with the surface, and their accurate calibration is essential to achieving believable material responses across different lighting environments and rendering engines such as Unreal Engine or Blender’s Eevee and Cycles.

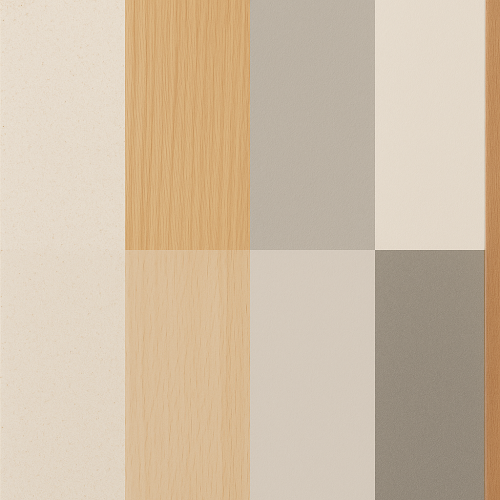

The albedo map for chipboard and MDF must primarily convey the diffuse color information without baked-in shadows or lighting artifacts. Given the engineered composition of chipboard—small wood chips bonded with resin—and the fine, homogeneous fiber structure of MDF, the albedo texture tends to exhibit muted, warm beige to light brown hues with subtle speckling or grain patterns depending on manufacturing processes and any finishing applied. Capturing this requires high-resolution photography under diffuse, neutral lighting or carefully scanned sources. Post-processing involves desaturating or balancing color channels to remove any color casts from the lighting and meticulously painting out any baked shading or highlights that would disrupt the physically based shading workflow. While chipboard may show slight darker inclusions representing wood chips, MDF’s surface is typically smoother and more uniform. To enhance realism, micro-variation in tone and faint grain patterns should be retained or subtly enhanced within the albedo map to prevent the material from appearing overly flat or synthetic when tiled across large surfaces.

Normal map generation is critical to simulating the small-scale surface irregularities that provide visual cues about the material’s texture. For chipboard, this entails capturing the roughness of the wood chips embedded in the resin matrix, which can manifest as small bumps, pits, and occasional ridges. MDF’s normal map, by contrast, should emphasize its finer, sanded surface texture with gentle undulations and a soft fibrous detail rather than pronounced wood grain. Creation can be achieved by photogrammetry with controlled lighting angles or through high-resolution scanning methods such as photometric stereo to isolate surface normals from diffuse color. Alternatively, procedural or hand-painted normal maps can be used in combination with scanned data to emphasize desired micro-details. Calibration of the normal map intensity within the material shader is crucial; excessive normal map strength can exaggerate the roughness and create unrealistic shading artifacts, while too little will flatten the surface appearance. Subtlety is key, especially for MDF, where the normal detail is delicate. Engine-specific normal map format considerations must be observed—for instance, Unreal Engine expects normal maps in tangent space with the green channel inverted compared to some other software, requiring appropriate adjustments during export.

Roughness maps for chipboard and MDF govern the microsurface scattering and glossiness, influencing how light reflects at varying viewing angles. These materials are generally matte, with roughness values skewed high (approaching 0.7 to 0.9) to simulate diffuse reflection rather than specular highlights. However, due to resin finishes or slight surface varnishing, certain areas may exhibit reduced roughness creating subtle variations in gloss. The roughness map should incorporate this heterogeneity, reflecting the composite nature of chipboard where resin pockets or compressed wood chips reflect light differently than fiber-rich MDF surfaces. Generation methods include capturing specular reflections under controlled lighting and converting the data into roughness values via inverse glossiness, or procedural painting guided by albedo and normal map features. Calibration involves iterative testing under directional and environment lighting in the target rendering engine to ensure the roughness values produce realistic reflections without appearing either plasticky or overly diffuse. Additionally, roughness maps must be carefully tiled and blended to avoid visible repetition patterns, often addressed by introducing noise or variation through secondary masks or detail maps.

Ambient occlusion maps enhance perceived depth by darkening crevices and areas occluded from ambient lighting, complementing the PBR workflow without being baked into albedo or other maps. For chipboard and MDF, AO maps are particularly important to accentuate the micro-crevices between wood chips or fiber clumps and subtle surface depressions. Generation typically involves baking AO from high-poly geometry or using ambient occlusion passes in photogrammetry software. Since both materials are relatively flat, AO maps often contain soft shadows rather than deep occlusion, but even minor variations improve the perception of surface complexity. Calibration requires balancing AO intensity so that it enhances detail without creating unnatural darkening that conflicts with global illumination or dynamic lighting in engines like Unreal Engine. Using AO as a multiply layer in the shader rather than baking it into albedo maintains flexibility for lighting adjustments.

Height or displacement maps provide geometric detail at a micro or macro scale and are particularly useful when combined with tessellation or parallax occlusion mapping in real-time engines. For chipboard, height maps should capture the unevenness from wood chip boundaries and resin matrix variations, creating a subtly bumpy surface. MDF’s height maps are typically smoother but can include fine surface imperfections and slight depressions from sanding or manufacturing. Height map generation can be derived from grayscale photogrammetry capture, converted from normal maps, or hand-painted to emphasize specific features. Calibration involves adjusting the displacement scale in the material to avoid exaggerated surface distortions that break silhouette or cause rendering artifacts. In Blender and Unreal Engine, careful tuning of displacement or parallax parameters ensures that the height data contributes convincingly to surface definition without compromising performance.

Metallic maps for chipboard and MDF are conventionally omitted or set uniformly to zero. These materials are non-metallic by nature, and any metallic reflections would be physically inaccurate. Maintaining a metallic value of zero simplifies the shader and prevents unintended specular highlights or reflections that would contradict the expected material response.

A significant challenge in calibrating PBR maps for chipboard and MDF lies in replicating the subtle interplay between micro-roughness, diffuse reflectance, and ambient occlusion under varied lighting conditions. Both materials tend toward low specularity and soft shadows, but slight manufacturing differences or finish coatings can alter their appearance markedly. Therefore, iterative testing within different lighting environments—direct sunlight, interior artificial lighting, and HDR environment maps—is essential. Artists can utilize Unreal Engine’s material instance parameters or Blender’s node groups to dynamically adjust roughness, normal strength, and AO intensity during previews. Employing physically accurate IBL (Image-Based Lighting) environments ensures that the material behaves consistently and provides reliable feedback for calibration.

Tiling and micro-variation further enhance realism by breaking up repetitive patterns that can betray the synthetic nature of engineered wood surfaces. Since chipboard and MDF textures are often applied over large planar surfaces such as cabinetry or furniture panels, introducing subtle randomization through detail masks, multi-texture blending, or procedural noise offsets mitigates noticeable repetition. This is especially important for the albedo and roughness maps, where uniformity can flatten the perceived surface complexity. Micro-variation in the normal map, achieved via detail maps or secondary normal layers, adds fine-scale bumpiness that responds dynamically to light direction, enhancing tactile realism.

In practice, optimizing these texture maps for real-time engines involves balancing resolution, channel packing, and compression artifacts. For instance, roughness, metallic, and ambient occlusion can be combined into a single RGB texture to reduce memory footprint, provided that careful calibration is done to maintain visual fidelity. Normal maps should be stored in formats supporting high precision and minimal compression artifacts, as these directly impact the perceived surface detail. When authoring in Blender, the node-based material system allows for flexible blending and layering of detail maps, facilitating the integration of base PBR maps with procedural micro-variation textures. Unreal Engine’s material editor offers robust tools to adjust map intensities and combine textures dynamically, enabling fine-tuning of the chipboard and MDF appearance in situ.

In summary, the creation and calibration of PBR maps for chipboard and MDF demand a nuanced approach that captures the materials’ composite structure, subtle surface texture, and matte reflectance properties. High-quality albedo maps free of baked lighting, finely calibrated normal and roughness maps emphasizing micro-details, appropriately balanced ambient occlusion, and carefully scaled height maps collectively contribute to a realistic portrayal of these engineered woods. Rigorous iterative testing under varied lighting and strategic tiling with micro-variation ensure that the textures maintain their authenticity and visual interest in diverse rendering scenarios. Mastery of these workflows and their integration into modern engines is essential for producing convincing chipboard and MDF materials in physically based rendering pipelines.